Tinkers Platform 1st

Privatization deployment Customized services Lightweight systems

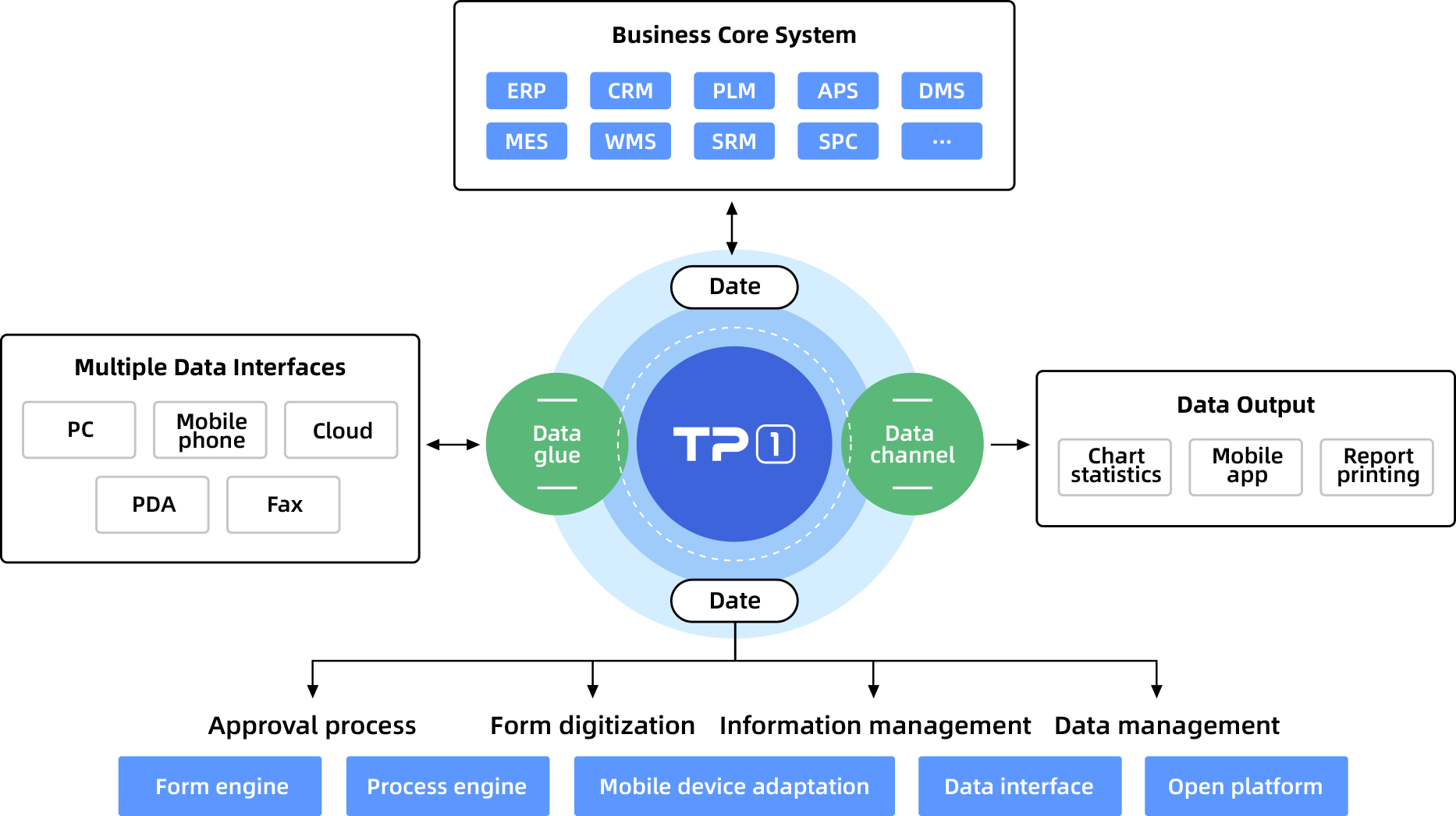

The "Data Glue" between systems connects the entire process and enables the interoperability of data

Zero Development and Full Configuration

Easy to use Low cost Fast delivery

Tinkers Platform 1st

Privatization deployment Customized services Lightweight systems

The "Data Glue" between systems connects the entire process and enables the interoperability of data

Zero Development and Full Configuration

Easy to use Low cost Fast delivery  Configuration of Processes and Forms Rapid building a multi-style form structure

Intuitive display of workflows and approval processes

Configuration of Processes and Forms Rapid building a multi-style form structure

Intuitive display of workflows and approval processes Building Structure Rapid prototyping of basic functions such as users, departments, and roles

No development import required

Building Structure Rapid prototyping of basic functions such as users, departments, and roles

No development import required Multiple Data Interfaces Being connected with various external data interfaces

No intrusion/destruction of the original system structure

The read data can be modified or reused.

Multiple Data Interfaces Being connected with various external data interfaces

No intrusion/destruction of the original system structure

The read data can be modified or reused. Dashboard Configuration Diverse dashboard plugins that support simple drag-and-drop functionality.

Dashboard Configuration Diverse dashboard plugins that support simple drag-and-drop functionality. Multi-Format Message Notification Flexible configuration for multi-channel message notifications, including email, SMS, and enterprise WeChat.

Multi-Format Message Notification Flexible configuration for multi-channel message notifications, including email, SMS, and enterprise WeChat.

Rapid response to business needs

Adapt to changing business needs

Rapid system deployment

Rapid presentation of system interfaces

Open customization platform

Support complex business processes

WYSIWYG form configuration

Electronic forms without development

Data Connection

Solving the data silo issue among systems and carrying business flow data to create an enterprise data middleware

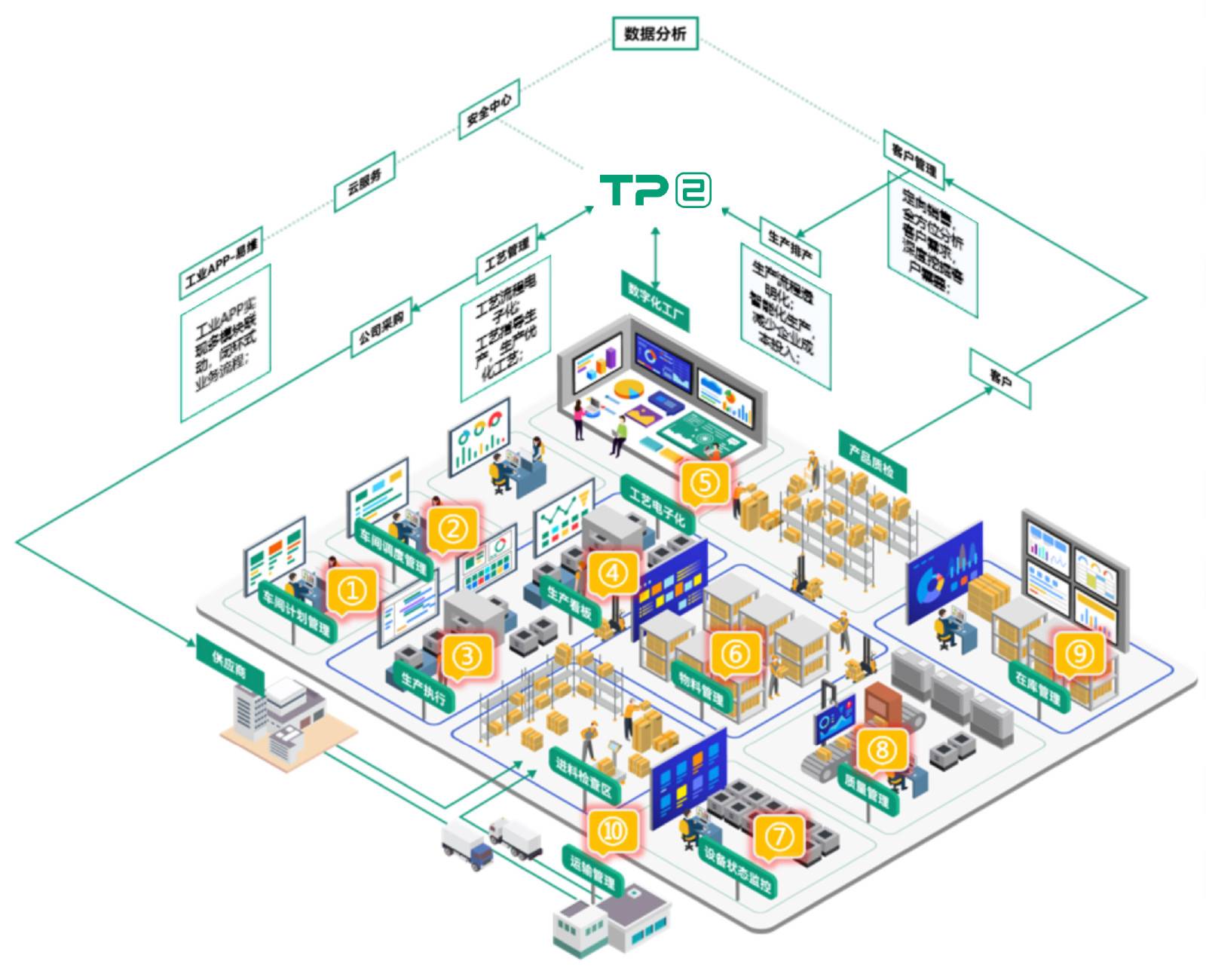

Tinkers Platform 2nd

SaaS Standardized system Data Integration Privatization deployment Customized service Equipment Leasing

Tinkers Platform 2nd

SaaS Standardized system Data Integration Privatization deployment Customized service Equipment Leasing

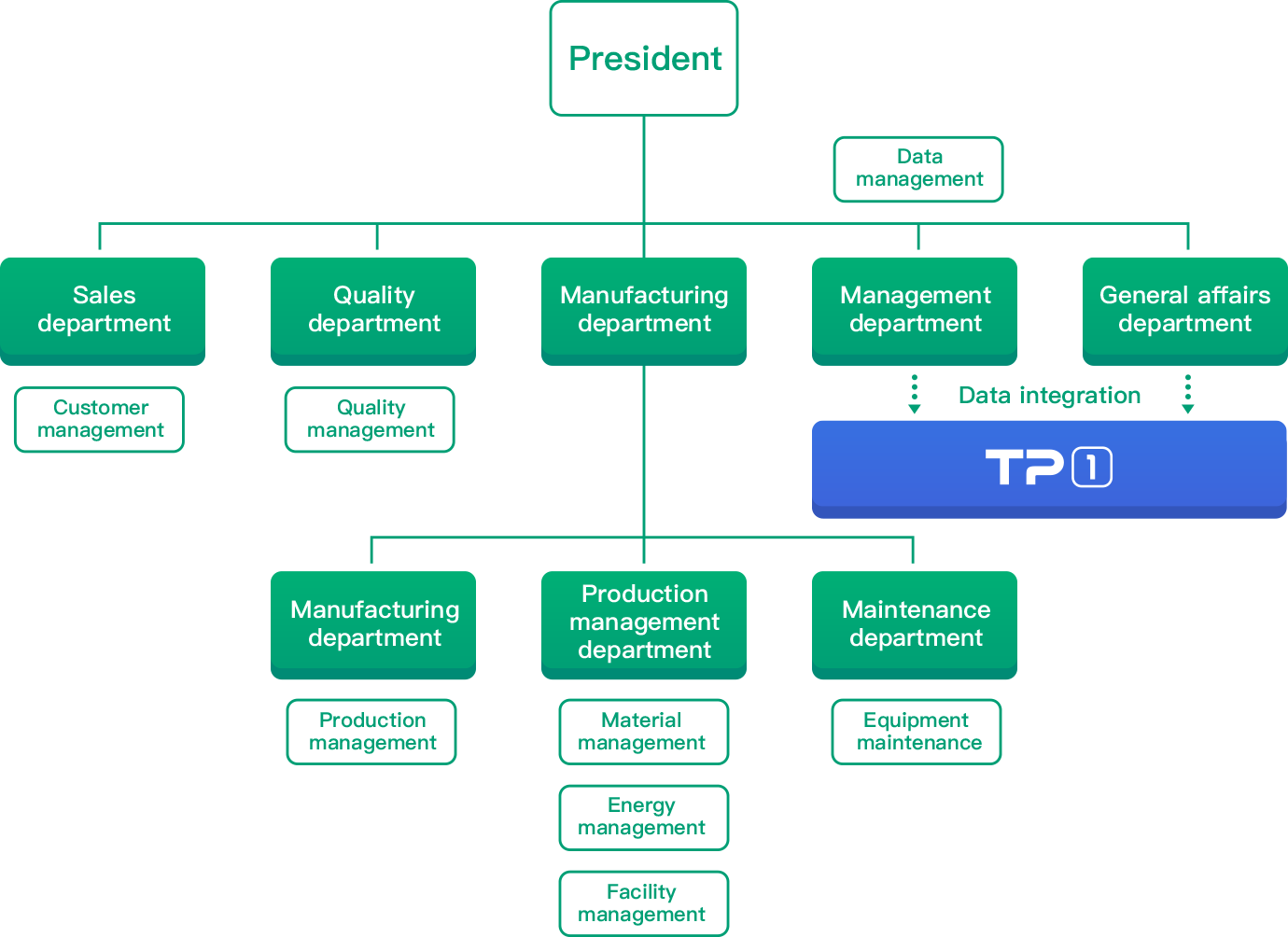

Organization structure based on manufacturing enterprises to meet the needs of different business scenarios

No need for IT infrastructure construction, ready to use upon selection

Full LifecycleBusiness Collaborative ManagementIntegrated Data AnalysisLean Process

Digital Factory

Vertically penetrating into the professional fields of the manufacturing industry with business scenarios as the starting point

TP2 Implementation Cases Display

Japanese automotive parts manufacturing company

Equipment security.KANBAN

Real-time on-site progress tracking and failures early warning

Knowledge base system to assist operations and form digital assets

Long-term data storage with traceability

Fast data acquisition, real-time sharing, and reproduction of real scenarios

UP

Task accuracy

Japanese well-known parts manufacturer enterprise

EMS module

Integrated facility energy monitoring in one-stop solution

2.5D factory scene display for complete energy management control

Refined energy consumption analysis with multidimensional monitoring

IoT device integration for increasing analysis reliability.

Down

Energy consumption

Infrastructure and monitoring in a city

SUT.AMS module

Facility and equipment lifecycle management, reducing the frequency of unstable factors

Real-time data collection and analysis to extend equipment life

Video monitoring, AI recognition, 3D visualization, stereo monitoring, and online scheduling.

UP

Efficiency of monitoring and management

Packaging products manufacturer enterprise

CRM.3DC module

Rapid formation of products

Component model library supporting multiple assembly forms

Online collaborative work for reducing labor costs

Comprehensive customer analysis

Efficiently identifying potential customers

Track sales opportunities throughout the process

UP

Customer retention rate

Packaging logistics integration service enterprise

MES.TMS module

Collaborative production with material coordination and scheduling

Lean production to meet production demands accurately

Traceable production process

Visualized transport routes with real-time vehicle movements monitoring

Intelligent dispatching to reduce enterprise costs

UP

Production efficiency

Japanese bicycle parts

manufacturer

SPC module

Improving customer satisfaction and increasing revenue

Accurate product quality control process

Reducing the time for quality inspection data entry, statistics, and analysis

Data trend warning to improve product qualification rate

UP

Quality improvement rate